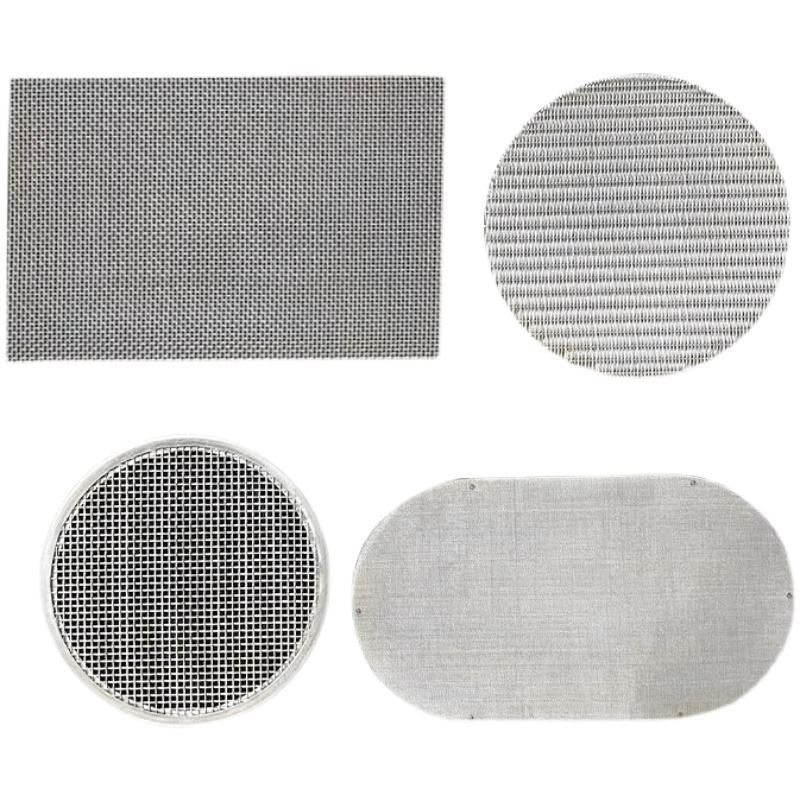

iStainless Steel Coffee Sintered Tablets

Izifundo ezisebenzayo

1. Cinezela umgubo wekhofi nge-tamper

2. Beka ubungakanani obufanelekileyo bemesh yokwahlula amanzi

3. Beka isiphatho somatshini wekofu kwintloko yokusela

4. Jonga ulwelo

Kutheni usebenzisa uthungelwano lwesibini lokuhambisa amanzi?

Umnatha wesibini wokusabalalisa amanzi uhlula ngokufanelekileyo i-powder powder kunye nentloko yokuphuza ukuze ihlale icocekile

Iimpawu ze-sintered mesh

1. Amandla aphezulu kunye nokuqina okulungileyo: Inamandla amakhulu omatshini kunye namandla oxinzelelo, ukulungiswa kakuhle, i-welding kunye nokusebenza kwendibano, kwaye kulula ukuyisebenzisa.

2. Ukuchaneka okufanayo kunye nokuzinza: Ukusebenza okufanayo kunye nokuhambelana kokucoca kunokufezekiswa kuzo zonke izichanekileyo zokucoca, kwaye i-mesh ayitshintshi ngexesha lokusetyenziswa.

3. Ubume bokusetyenziswa ngokubanzi: Ingasetyenziswa kwindawo yobushushu -200 ℃ ~ 600 ℃ kunye nokuhluzwa kwe-asidi kunye nokusingqongileyo kwealkali.

4. Ukusebenza okugqwesileyo kokucoca: isiphumo esihle sokucoca i-countercurrent, sinokusetyenziswa ngokuphindaphindiweyo, kwaye sinobomi benkonzo ende (inokucocwa ngamanzi aphikisanayo, i-filtrate, i-ultrasonic, i-melting, i-baking, njl.).

Inkqubo yemveliso yeSintering

1. Iqondo lobushushu eliphantsi laphambi kokutshisa inqanaba.Ngeli nqanaba, ukubuyiswa kwesinyithi, i-volatilization yegesi ye-adsorbed kunye nomswakama, ukubola kunye nokususwa kwe-ejenti yokwenza kwi-compact kwenzeka kakhulu;

2. Inqanaba lobushushu eliphakathi lokufudumeza inqanaba le-sintering.Kweli nqanaba, i-recrystallization iqala ukwenzeka.Kwiingqungquthela, iinkozo ezikhubazekileyo zibuyiselwa kwaye zilungelelaniswe kwakhona zibe ziinkozo ezintsha.Ngexesha elifanayo, i-oxides ebusweni iyancitshiswa, kwaye i-particle interface yenza intamo ene-sintered;

3. Ukugcinwa kobushushu obuphezulu kugqiba inqanaba le-sintering.Ukusasazwa kunye nokuhamba kweli nqanaba kuqhutywe ngokupheleleyo kwaye kusondele ekugqityweni, ukwenza inani elikhulu leembobo ezivaliweyo, kwaye ziqhubeke zinciphisa, ukwenzela ukuba ubukhulu bepore kunye nenani elipheleleyo leepores liyancipha, kwaye ubuninzi bomzimba osikiweyo bubaluleke kakhulu. anda.